We are proud to announce we are the "Afinia UK & Overall Dealer of the Year for 2024"

At the start of summer 2024 Sauce Shed got in touch with HD Labels to talk through their need to produce labels in house.

So how did we go from this, to supplying both label and packaging printers and finishers before the summer was up?

Who are Sauce Shed?

Sauce Shed are a leading private label manufacturer of artisan, hand crafted sauces. From product development to large scale sauce production. Sauce Shed has the flexibility to work with either small or large batch production.

What were their requirements?

Sauce Shed came to HD Labels with a need to produce professional labels in-house but to any shape or size, in all sorts of volumes and ideally quickly. As they were creating products for their customers the artwork could vary in size and shape as well as material type. One label could be rustic looking and the next foil and futuristic. They needed something that offered this flexibility.

What did we supply Sauce Shed?

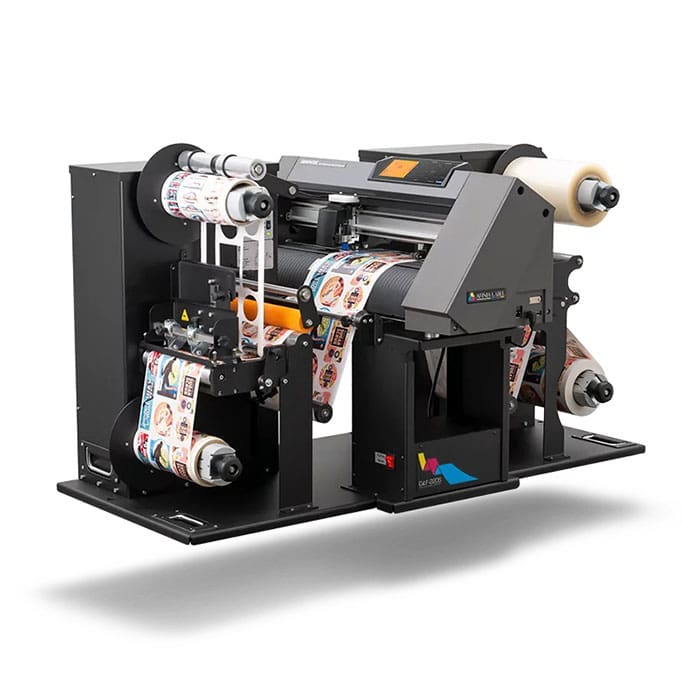

On our first trip to Sauce Shed we delivered the OKI Pro 1050 and Afinia DLF140s. These two machine combined allowed Sauce Shed to print onto a range of continuous label materials on the OKI Pro 1050 and then laminate and cut the labels on the Afinia DLF140s.

While onsite our the customer was discussing other requirements they had and by the time we left they had ordered a OKI Pro 9542 along with a Gemini finisher. These were to allow them to produce their own boxes in house and print directly onto pouches.

Why did they choose the machines they did?

In-House Label Solutions – OKI & Afinia

The OKI PRO 1050 is the ideal solution for those wanting a variety of media types and the ability to print white.

By combining this with the Afinia DLF140s label finisher, Sauce Shed have an in-house solution for servicing their customers varying requirements for shapes, sizes, and finishes. Its fast and efficiently without set up costs and with minimal wastage.

The Afinia DLF140s finisher can also be used to add laminates before cutting which can alter the finish, increase the label thickness and add extra durability / a more luxurious feel to your label.

Why did they choose the machines they did?

In-House Packaging Solutions – OKI & Afinia

The OKI Pro 9542 is an exceptional printer of flat products and when paired with the Gemini you get a great solution for short run, packaging production. The OKI Pro 9542 can print on flat sheet paper, card, sheet labels and even certain pouches. It again uses 5 colours which can give you a great mix of print finish just like the Pro 1050 label printer above.

One key feature is the ability to produce short run boxes to any shape or size. This is great for prototyping or short run production. If Sauce Shed produce a batch of sauce they can now produce the labels and packaging in-house on the same day. The Gemini will cut and crease the boxes so they’re easily built after cutting.