Overlaminates are rolls of clear, usually polyester or polypropylene material that is applied over the top of the printed label material before the materials are cut to shape. They increase the durability, add thickness and provide protection to the print. For certain applications overlaminate can be an essential component of the label construction.

When applied well an overlaminate should barely be noticeable to the person viewing your label. Laminates are most frequently used to protect and increase the durability of the label from smudging or scratching, particularly when inks have been used for the print, however they can also serve to alter the aesthetics of the label. A gloss PP material for example can be used as a base to enhance any vibrant colours but a matt overlaminate used to change the finish. A silver shiny base material can be given a totally different more chrome type effect with the addition of a matt over laminate.

While there are no set rules for which finish is best cosmetics and pharmaceuticals often opt more for a matt finish and food packaging is more often than not gloss laminated. The colours and design of the label should also be taken into consideration when deciding on which laminate to use.

HD Labels supply both rolls of backed and self wound (backless) laminate in gloss or matt finish, and also in different thicknesses for those with their own finishers. Our short run print service also has the option to add a laminate to any of our in-house printed labels.

Contact your one of our team if you would like any help, advice or samples.

Left: Afinia DLP2100 Video

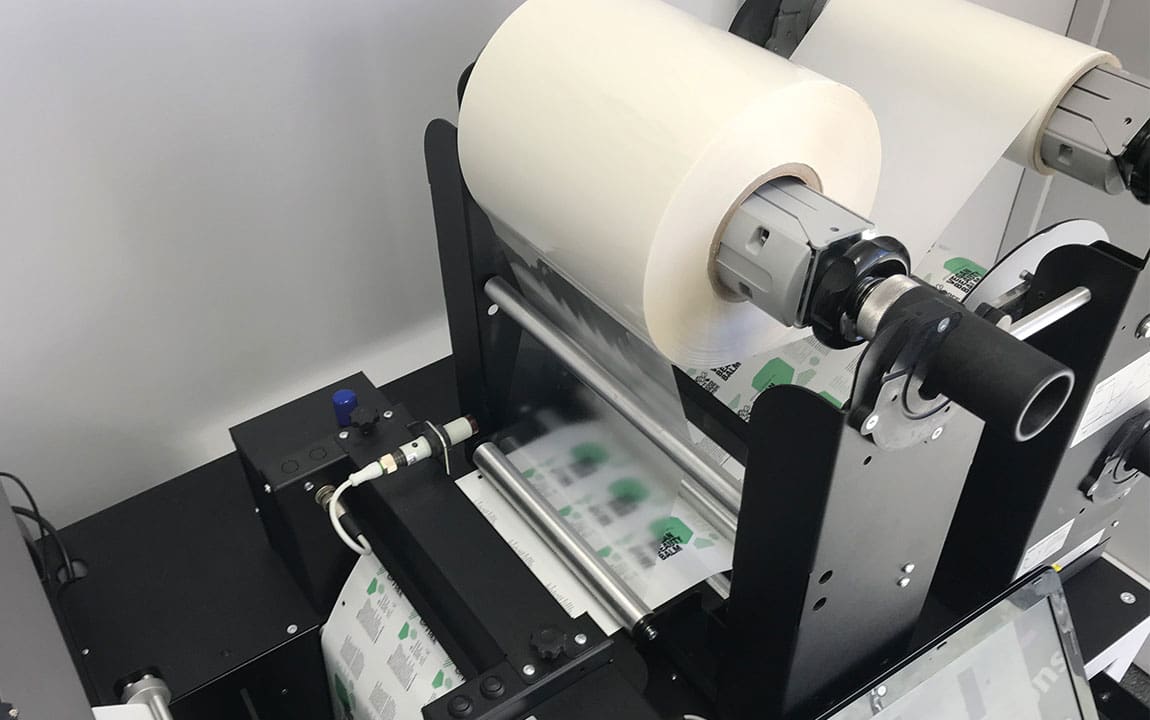

Clear Gloss Laminate being applied to continuous material before being die cut on the Afinia DLP2100