Most modern thermal printers these days can print using either direct thermal or thermal transfer so you’re most likely covered for both. But what do these two options mean and when would you use either direct thermal or thermal transfer?

Well our latest edition of “Label Talk” explains all of this. Please watch the video below or to recap we’ve created some bullet points below that.

Direct Thermal Printing

What’s involved when printing direct thermal labels?

- You need coated “direct thermal” labels and you can’t just use any label.

- You DO NOT need a ribbon of any kind in the printer.

- This is the cheapest and most common form of thermal printing.

Why would you use direct thermal?

- Direct thermal is for those needing short life labels.

- The labels will last months rather than years and will start to fade potentially within weeks depending how they’re stored.

Which applications would use direct thermal?

- Shipping labels – Usually only need to last a day or so as once the parcel is received the label is no longer needed.

- Short life ingredients labels – Products such as sandwiches, baked goods, fresh food or anything that won’t last long nearly always has a direct thermal label on it. Butchers scales or fish counters still use short life (direct thermal) labels to seal your product and explain the contents.

Thermal Transfer Printing

What’s involved when printing thermal transfer labels?

- You can usually print on any smooth finish label material.

- You DO need a ribbon. These are usually made of wax or resin. Resin being the most durable.

- This is slightly higher in cost than direct thermal but both options are very cheap.

Why would you use thermal transfer?

- Thermal transfer is for those needing long life labels.

- Depending on the ribbon and material you use. Your labels could last years and survive very harsh environments.

Which applications would use thermal transfer?

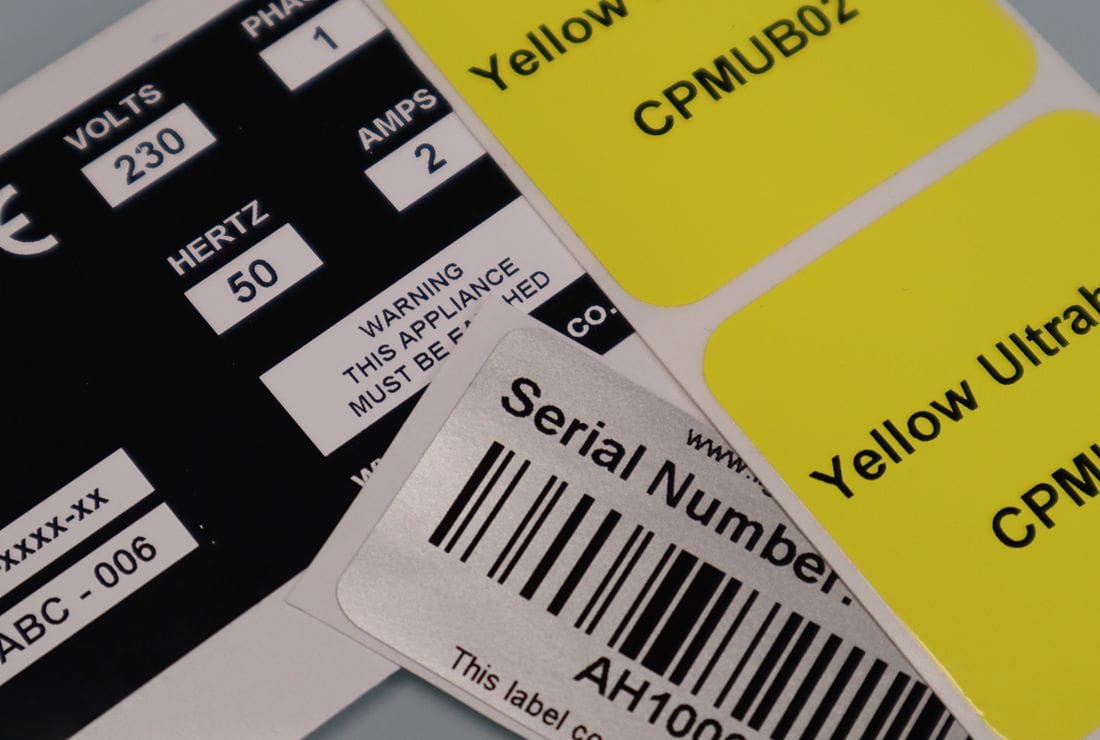

- Safety / warning labels – Obviously a safety or warning label is important and needs to remain legible for the life of the product it’s on so it can’t fade or wipe off. Thermal transfer offers this.

- Asset / serial number / product labels – Labels that might be stored in potentially harsh environments such as an asset label on air con units or machine parts. Serial numbers or something that still needs to be readable 10 years from now.